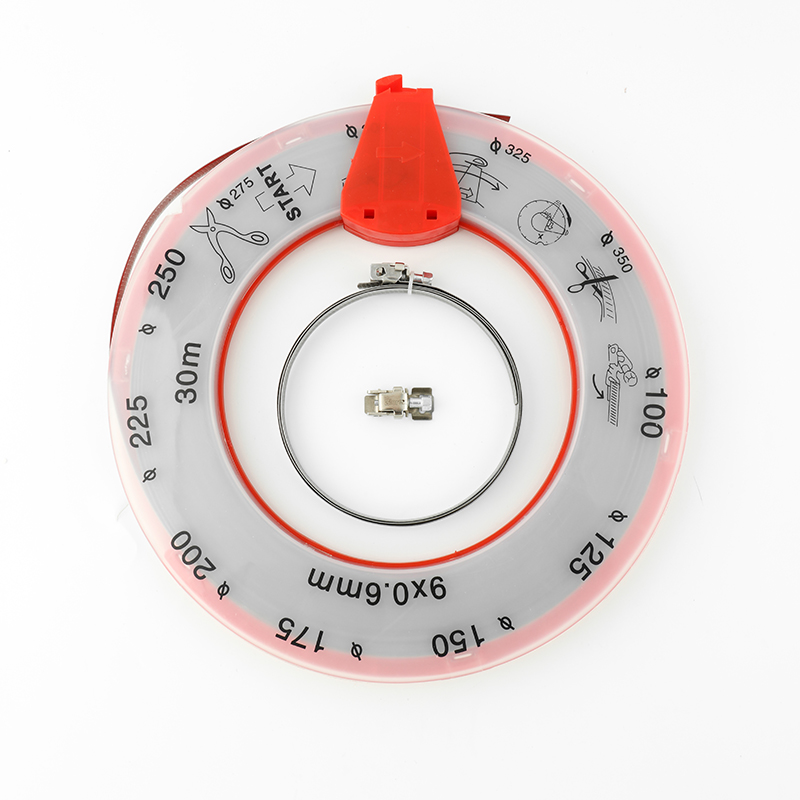

Germany Type DIN3017 Hose Clamp – Stainless Steel Radiator Hose Clips

Introducing the hose clamp conforming to German DIN3017 standard: the ultimate solution for safe and reliable hose connections.

For ensuring the integrity of hose connections, German DIN 3017 type hose clamps are the preferred choice. These stainless steel hose clamps are precision-manufactured, durable, and meet the highest performance and reliability standards. Whether you are in the automotive, plumbing, or industrial sectors, our German hose clamps can perfectly meet all your clamping needs.

| Material | W1 | W2 | W4 | W5 |

| Hoop staps | Iron galvanize | 200ss/300ss | 200ss/300ss | 316 |

| Hoop shell | Iron galvanize | 200ss/300ss | 200ss/300ss | 316 |

| Screw | Iron galvanize | Iron galvanize | 200ss/300ss | 316 |

Excellent design and construction

The DIN3017 German-style hose clamp features an innovative extruded toothed structure for a secure grip on the hose. Available in 9mm and 12mm widths, the clamp is designed for a wide range of clamping angles, making it versatile for various applications. Its unique design ensures the hose is not flattened or cut during installation and final torque application, which is crucial for maintaining connection integrity.

Reusability and Stability

One of the highlights of our stainless steel hose clamps is their reusability. Unlike many traditional clamps that may fail after a single use, DIN3017 clamps can be reused multiple times without affecting their sealing performance. This not only makes them an affordable option but also helps maintain a more stable seal over the long term. Even under pressure variations, you can rest assured that your connection remains strong and reliable.

Widely applicable

DIN 3017 German standard hose clamps are suitable for a variety of applications. Whether you are securing hoses in automotive systems, piping installations, or industrial machinery, these clamps provide the reliability you need. Their robust construction and careful design make them ideal for both high and low pressure environments, ensuring your hoses are securely in place.

Corrosion resistance

Our German-made hose clamps are made of high-quality stainless steel, making them corrosion-resistant and rust-proof, suitable for various harsh environments. Their superior durability ensures the clamps will stand the test of time, giving you peace of mind and protecting hose connections from the effects of harsh conditions.

Easy to install

The DIN 3017 German standard hose clamp is easy and quick to install. Its design allows for easy installation, enabling you to quickly and efficiently secure hoses. Its simple tightening mechanism allows you to easily achieve the required torque without worrying about over-tightening and causing damage.

In conclusion

In summary, the DIN 3017 German standard hose clamp is an essential tool for anyone seeking safe and reliable hose connections. With its superior design, reusability, and corrosion resistance, this stainless steel hose clamp is ideal for a wide range of applications. Whether you are a professional or a DIY enthusiast, you can rely on the quality and performance of our German hose clamps to meet your needs. Invest in DIN 3017 German standard hose clamps today and experience the superior performance of your hose connection solutions!

| Specification | Thickness(mm) | Bandwidth(mm) | Diameter Range(mm) | Mounting Torque(Nm ) | Material | Surface Finish |

| 201 Semi steel 8-12 | 0.65 | 9 | 45881 | Load torque ≥8Nm | 304 Stainless steel | Polishing process |

| 201 Semi steel 10-16 | 0.65 | 9 | 45946 | Load torque ≥8Nm | 304 Stainless steel | Polishing process |

| 201 Semi steel 13-19 | 0.65 | 9 | 13-19 | Load torque ≥8Nm | 304 Stainless steel | Polishing process |

| 201 Semi steel 12-20 | 0.65 | 9 | 46011 | Load torque ≥8Nm | 304 Stainless steel | Polishing process |

| 201 Semi steel 12-22 | 0.65 | 9 | 46013 | Load torque ≥8Nm | 304 Stainless steel | Polishing process |

| 201 Semi steel 16-25 | 0.65 | 9 | 16-25 | Load torque ≥8Nm | 304 Stainless steel | Polishing process |

| 201 Semi steel 16-27 | 0.65 | 9 | 16-27 | Load torque ≥8Nm | 304 Stainless steel | Polishing process |

| 201 Semi steel 19-29 | 0.65 | 9 | 19-29 | Load torque ≥8Nm | 304 Stainless steel | Polishing process |

| 201 Semi steel 20-32 | 0.65 | 9 | 20-32 | Load torque ≥8Nm | 304 Stainless steel | Polishing process |

| 201 Semi steel 21-38 | 0.65 | 9 | 21-38 | Load torque ≥8Nm | 201 Stainless steel | Polishing process |

| 201 Semi steel 25-40 | 0.65 | 9 | 25-40 | Load torque ≥8Nm | 201 Stainless steel | Polishing process |

| 201 Semi steel 30-45 | 0.65 | 9 | 30-45 | Load torque ≥8Nm | 201 Stainless steel | Polishing process |

| 201 Semi steel 32-50 | 0.65 | 9 | 32-50 | Load torque ≥8Nm | 201 Stainless steel | Polishing process |

| 201 Semi steel 40-60 | 0.65 | 9 | 40-60 | Load torque ≥8Nm | 201 Stainless steel | Polishing process |

| 201 Semi steel 50-70 | 0.65 | 9 | 50-70 | Load torque ≥8Nm | 201 Stainless steel | Polishing process |

| 201 Semi steel 60-80 | 0.65 | 9 | 60-80 | Load torque ≥8Nm | 201 Stainless steel | Polishing process |

| 201 Semi steel 70-90 | 0.65 | 9 | 70-90 | Load torque ≥8Nm | 201 Stainless steel | Polishing process |

| 201 Semi steel 80-100 | 0.65 | 9 | 80-100 | Load torque ≥8Nm | 201 Stainless steel | Polishing process |

| 201 Semi steel 90-110 | 0.65 | 9 | 90-110 | Load torque ≥8Nm | 201 Stainless steel | Polishing process |

Product advantages:

1.Sturdy and durable

2.The cimped edge on both sides has a protective effect on the hose

3.Extruded tooth type structure, better for hose

Fields of application

1.Automotive industy

2. Madhinery industy

3.Shpbuilding industry (widely used in various industies such as automobile, motorcyde, towing, mechanical vehicles and industral equipment, Oil circuit, water cannel, gas path to make the pipeline connection seal more firmly).